|

Thermal International CO.,LTD

|

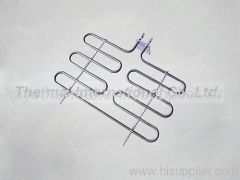

100V-400V Coil Heaters for Plastic Processing Machinery

| Payment Terms: | T/T,WU;Paypal |

| Place of Origin: | Guangdong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Feature

1) Use high purity mgo powder. Heaters enjoys good heat conduction and electric property

2) Coil heater is used in high outp

100V-400VCoil heaters for Plastic Processing Machinery is known as cable heaters can be formed to a variety of shapes as required by its many applications. Frequently though, coil heaters are configured as small diameter, high performance nozzle heaters that are fully annealed. Coil heaters are used on injection molding machine nozzles and sprue bushings supplying 360o of heat with optional distributed wattage models also available. Coil heaters are also used as cartridge heaters where irregular size bores are found. A straight, round cable heater can snake through a sealing bar in packaging equipment installations.

Specification

Model/ section:

DS1(Single head outlet wire ring shape):Φ1.6, Φ1.8, Φ2.0, Φ3.0, Φ3.3, Φ3.8, Φ5.0

DS2(Single head outlet wire square):1.5*2.1,1.7*3.5,2*4,2.2*4.2,2.7*4.5,4.2*6.5

DS3(Single head outlet wire square):3*3,3.5*3.5,4*4

SS1(Single head outlet wire ring shape):Φ1.6-5.0,6.6,8.0,8.5,10.0

SS2(Single head outlet wire square):6*6,8*8

Outer Material:SS304, SS321.

Inside Material: Ni80Cr20 resistance wire, high purity mgo powder

Heater surface temperature:750℃

In-put current:100V-400V.

Cold voltage tolerance: +5%-10%.

Insulation Resistance DC1000V(Un-heated):≥100MΩ.

Leakage Current: ≤0.5mA.

Model/ section:

DS1(Single head outlet wire ring shape):Φ1.6, Φ1.8, Φ2.0, Φ3.0, Φ3.3, Φ3.8, Φ5.0

DS2(Single head outlet wire square):1.5*2.1,1.7*3.5,2*4,2.2*4.2,2.7*4.5,4.2*6.5

DS3(Single head outlet wire square):3*3,3.5*3.5,4*4

SS1(Single head outlet wire ring shape):Φ1.6-5.0,6.6,8.0,8.5,10.0

SS2(Single head outlet wire square):6*6,8*8

Outer Material:SS304, SS321.

Inside Material: Ni80Cr20 resistance wire, high purity mgo powder

Heater surface temperature:750℃

In-put current:100V-400V.

Cold voltage tolerance: +5%-10%.

Insulation Resistance DC1000V(Un-heated):≥100MΩ.

Leakage Current: ≤0.5mA.

Feature

1) Use high purity mgo powder. Heaters enjoys good heat conduction and electric property

2) Coil heater is used in high output and high requirement molding.

With Accurate processing equipment and high-tech producing technology, coil heaters can stand different types mold's bending under 1050℃ heat treatment.

Related Search

Plastic Processing Machinery

Processing Machinery

Food Processing Machinery

Metallic Processing Machinery

Flour Processing Machinery

Food Machinery Processing

More>>